Cutting costs as a business can be difficult. Where in your business lies the most opportunity and quickest return? Are the results measurable? Is your business better off due to the cuts or are you required to give something up? Businesses face these types of tough questions every day without realizing part of the solution might be energy. Interestingly enough, energy is often overlooked as a cost-cutting solution.

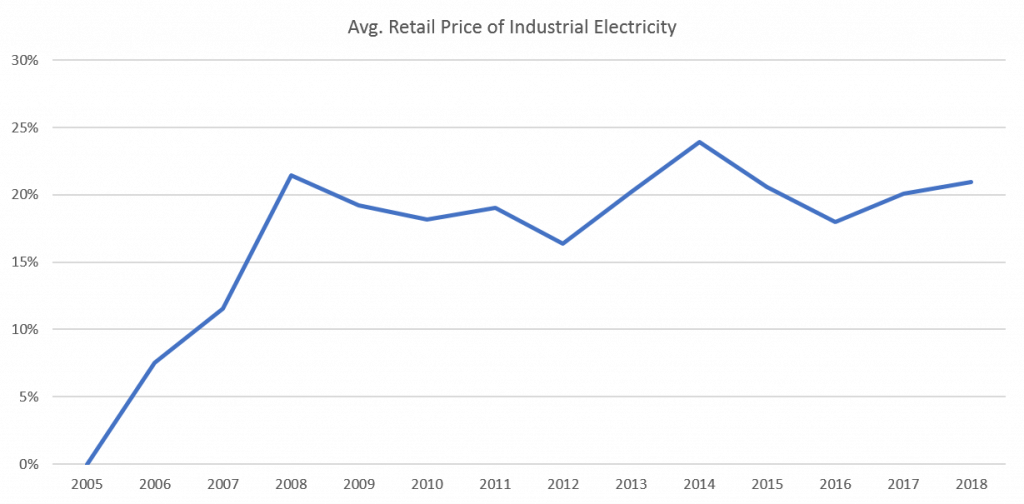

In the industrial manufacturing industry, energy usage is a significant cost of doing business. If history is any sign of the future, this cost will only continue to rise. According to the US Energy Information Administration (2016), prices have risen approximately 20% in just the last 12 years (See “Average Retail Price of Industrial Electricity” Chart).

Taking this into consideration, if emergence from the country’s recession has taught us anything, it is that lean and mean is the new standard. Meaning, it is more important now than ever for the manufacturing industry to actively manage and reduce energy costs when and where they can. However, where in your plant lies the most opportunity for energy savings? Where is the low hanging fruit and what solutions will provide the quickest returns? As many plants across the country have already discovered, lighting is one of them, offering substantial energy savings along with many other benefits.

Energy Savings

With recent advancements in technology, interior and exterior LED lighting offers a significant opportunity for energy savings. So much so, that the average plant can often reduce anywhere from 55%-75% of their annual lighting energy usage. Even though lighting is not typically a large percentage of a plant’s overall electrical load, this reduction can still equate to significant monetary savings.

With recent advancements in technology, interior and exterior LED lighting offers a significant opportunity for energy savings. So much so, that the average plant can often reduce anywhere from 55%-75% of their annual lighting energy usage. Even though lighting is not typically a large percentage of a plant’s overall electrical load, this reduction can still equate to significant monetary savings.

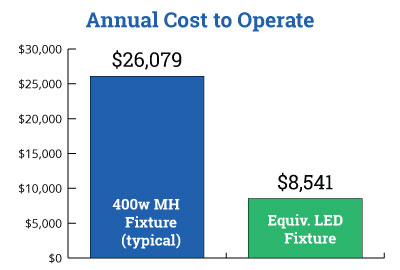

For example, consider the operating cost of 100 400-watt metal halides (MH), which are typical in manufacturing plants, compared to the equivalent energy efficient LED solution.

As depicted by the “Annual Cost to Operate chart” the differences in fixture operating costs are extreme. Shockingly, these 100 fixtures represent only 5% to 10% of the average plant’s fixture count. Furthermore, plants can bolster their savings by another 25%-50% with the addition of dimming motion sensors and controls. While lighting is one of the low hanging fruits of energy savings, lighting maintenance savings offer another cost-cutting opportunity for plants.

Maintenance Savings

Most plants have lighting fixtures within their facilities that are located in high, hard to reach places or above heavy-duty machinery. Unfortunately, these unavoidable obstacles make it difficult and costly to replace failed lamps and ballasts. Because of this, burned out lamps are often not replaced, leaving the plant insufficiently lit, which affects worker productivity and creates undesirable safety concerns.

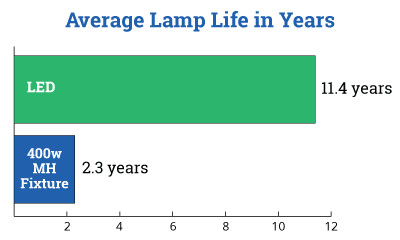

New energy efficient lighting technology provides longer lamp lives compared to metal halides. For example, a typical metal halide lamp will have an estimated rated life of 20,000 hours (2.2 years) in a plant operating 24/7. On the other hand, LED fixtures can have a rated life of up to 100,000 hours (11.4 years) in a 24/7 operating environment. With many of these LED fixtures coming with 10-year warranties, plants can virtually eliminate the cost and need for lamp replacements. This equates to significant monetary savings in replacement costs and ensures that the plant is properly lit year-round.

New energy efficient lighting technology provides longer lamp lives compared to metal halides. For example, a typical metal halide lamp will have an estimated rated life of 20,000 hours (2.2 years) in a plant operating 24/7. On the other hand, LED fixtures can have a rated life of up to 100,000 hours (11.4 years) in a 24/7 operating environment. With many of these LED fixtures coming with 10-year warranties, plants can virtually eliminate the cost and need for lamp replacements. This equates to significant monetary savings in replacement costs and ensures that the plant is properly lit year-round.

Increased Light Levels

Poorly lit facilities can decrease worker productivity and create unnecessary safety concerns. While energy efficient lighting upgrades reduce energy usage, they also offer significant increases in both lighting intensity and quality. On average, plants can expect a 10%-15% increase in lighting intensity by upgrading. This increase is further augmented with the utilization of 5000k, daylight, color temperature LED fixtures. The following pictures were taken before and after a plant’s lighting upgrade where the facility went from 464-watt 2700k High-Pressure Sodium (HPS) lamps to 118-watt 5000k LED fixtures.

Overall, as energy efficiency technologies continue to evolve, the more opportunities the engineered wood industry will have to not only lower, but manage and control their energy usage. Lighting technology has evolved through major advancements in the last five years and is currently on the forefront of viable cost-saving opportunities. Taking into account that electricity prices are going to continue to rise, managing energy usage now is an imperative step in ensuring the long-term success of any business.